For the machining centers in the new era, the tool change efficiency and stability of the tool magazine directly affect the production efficiency. Having a high-performance tool changer can make production work more powerful and bring efficient benefits.

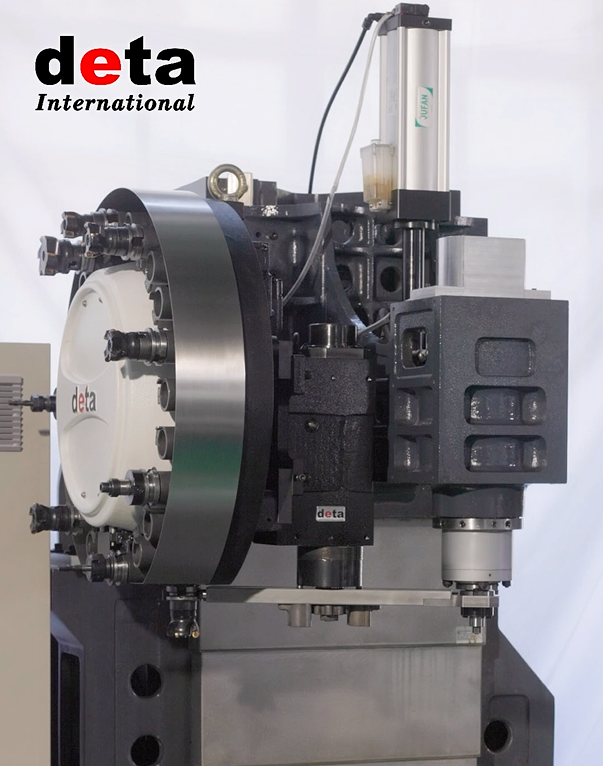

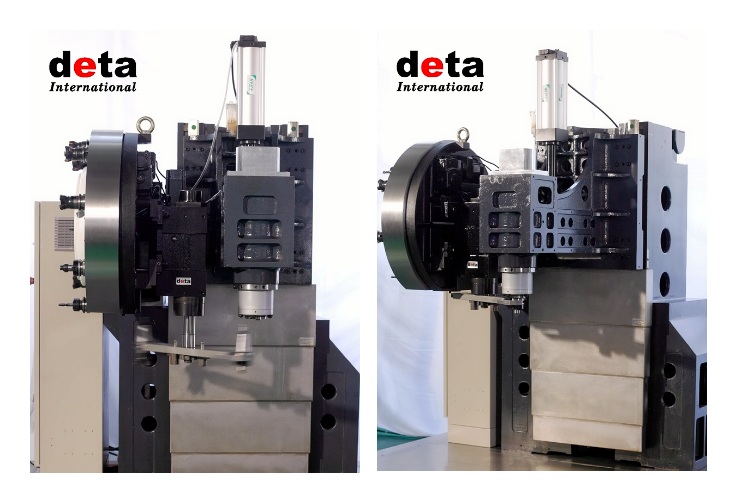

The following is the #40-24T knife double servo linkage knife arm tool magazine-model R4ALV

The tool magazine is driven by servo. When the servo motor is set at 2000 revolutions per minute, it only takes 0.15 seconds to switch to the adjacent tool position, which can solve the problem of changing a tool within 7 seconds for C-to-C machining, and effectively prevent the tool from being unbalanced. The problem of inaccurate positioning can also avoid the physical vibration of the pre-selected tool in the tool magazine during spindle machining, which affects the machining accuracy.

The cam box is also driven by servo, which can easily set two tool change modes, light and heavy, so that customers can immediately correct the speed according to the usage situation.

When the light knife is 3 kg, it is recommended that the servo motor be set at 1600 revolutions per minute, and the time for the cam box to rotate one revolution is 0.9 seconds. Second. Because the tool change is driven by servo, the speed and positioning are more accurate and stable, which can make the knife use more intelligent.

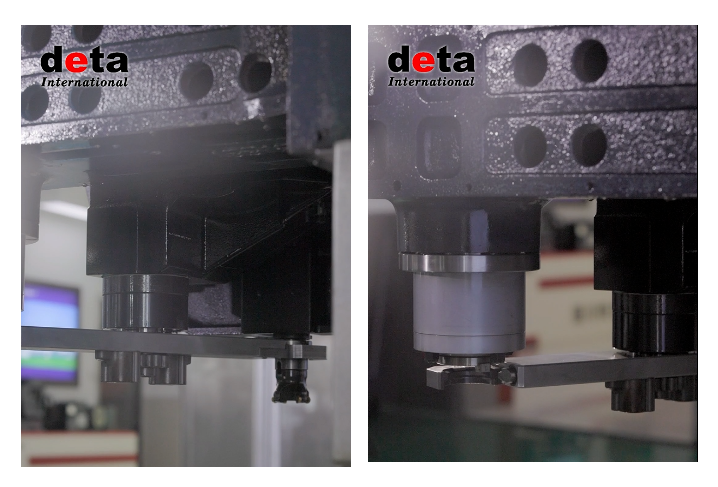

The knife arm adopts a three-stage linkage knife arm, which is called a silent buckle knife on the market.

This type of knife arm is a patented product of Deda. Because the top claw is in the retracted state when the tool is quickly changed, it will directly impact the tool rod on the spindle when the tool is buckled, especially for the spindle using ceramic bearings and precision bearings. To protect the effect, it can reduce the impact of the top claw of the buckle when the tool is changed quickly. Only by speeding up the tool change process under the condition of ensuring stability and accuracy can the processing efficiency be significantly improved, the processing time can be greatly shortened, the production cost can be reduced, and more can be added for customers. Much added value.

About the #40-24T knife double servo linkage arm tool magazine, do you understand it? If you have any questions, please contact us~

Home

Home Products

Products Telephone

Telephone Message

Message