Many customers do not know how to choose the tool magazine model. In this issue, the German lecture hall will introduce the R4ALTK tool magazine. It is aimed at three-axis moving column machines, small gantry-type machining centers, and portal-type vertical machining centers. Because of the position of the column, and R & D and development of this type of tool magazine, the installation position of this tool magazine is flexible, the tool arm is short, the tool changing speed is fast, and it can perfectly avoid workpiece interference. Let’s learn about it with the editor now~

01 configuration

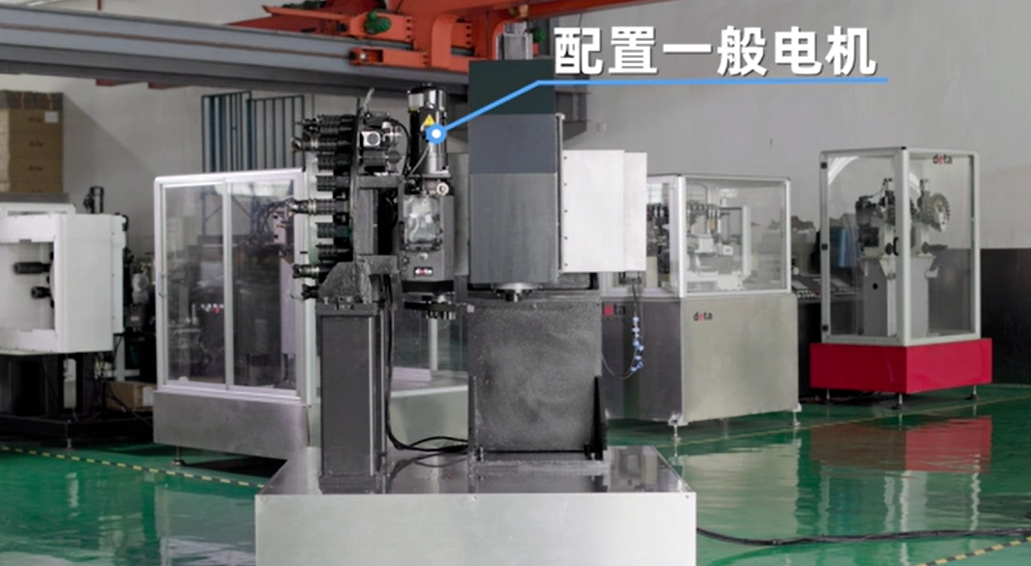

The R4ALTK exhibition machine introduced this time

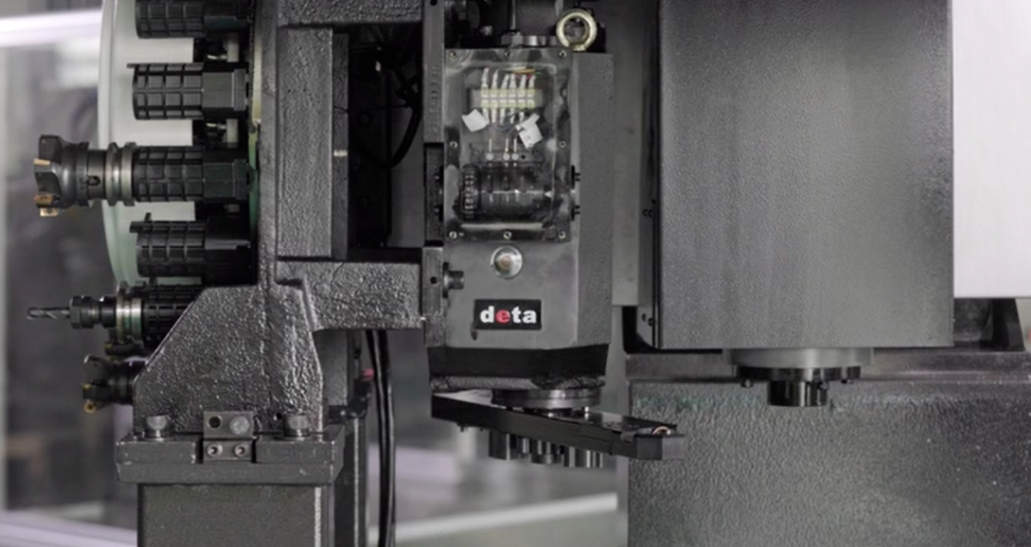

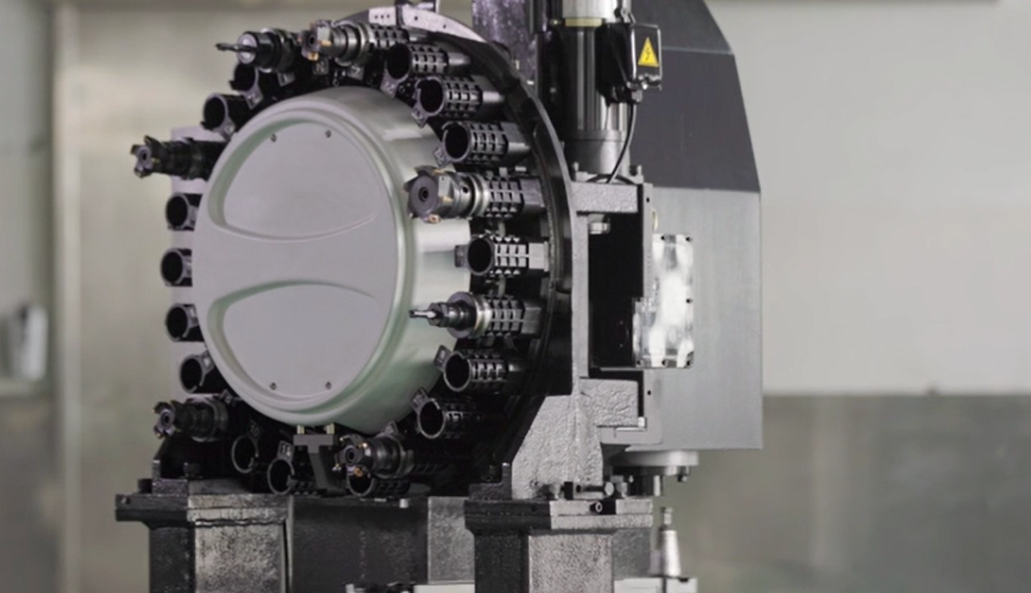

It is a disc type with 40 handles and 24 knives

The two drives of the tool magazine are general motors, and servo motors are also optional

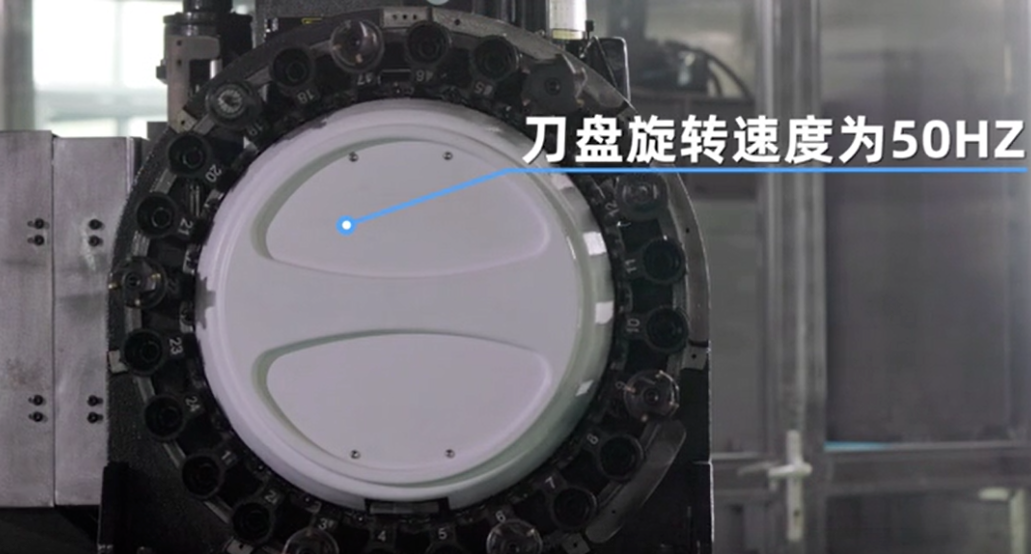

Generally, the rotation speed of the cutter head under the condition of 50Hz driven by the motor is 0.8 seconds to divide a cutter position.

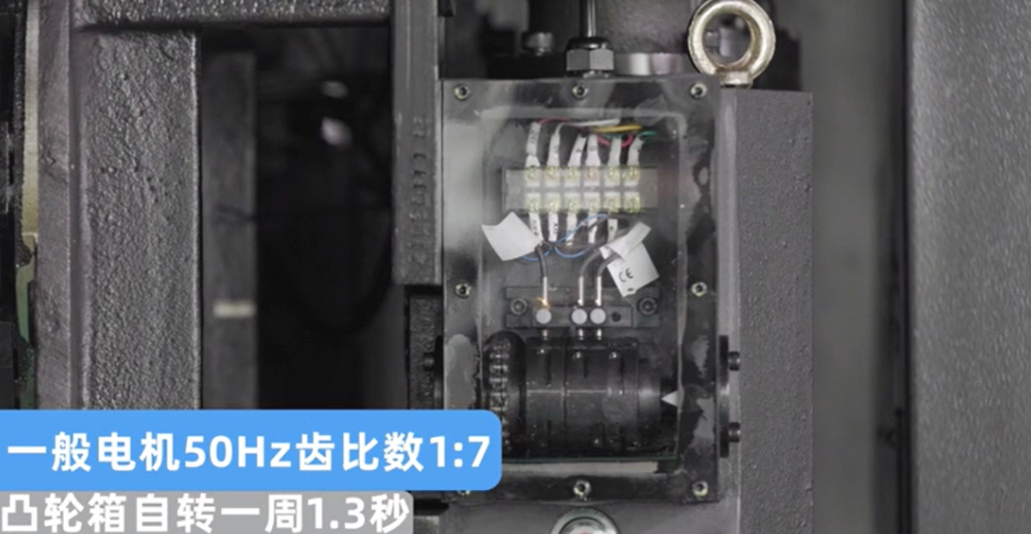

The rotation speed of the knife arm is generally 1:7 in the gear ratio of the motor. Under the condition of 50Hz, it takes 1.3 seconds for the cam box to rotate a circle.

02 The biggest feature of the tool magazine

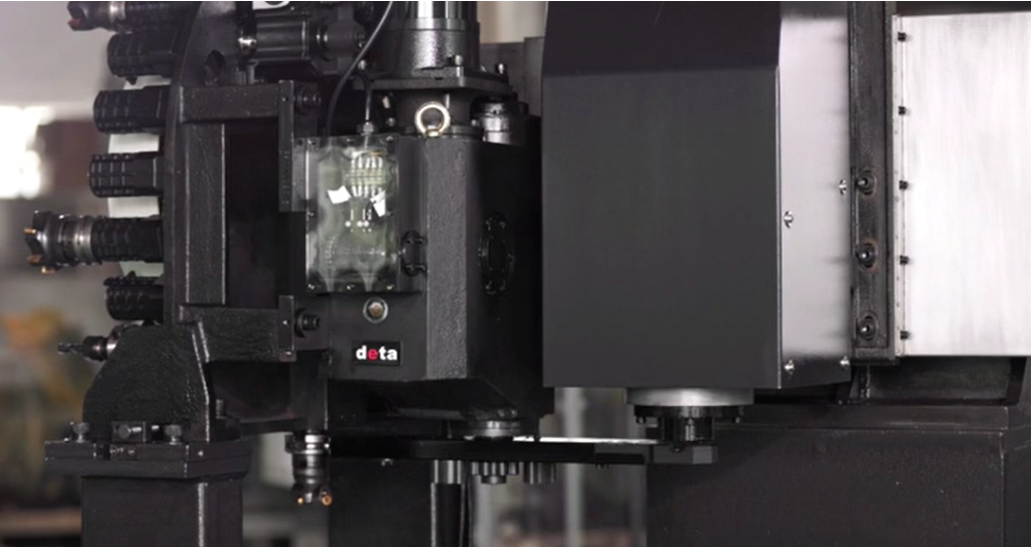

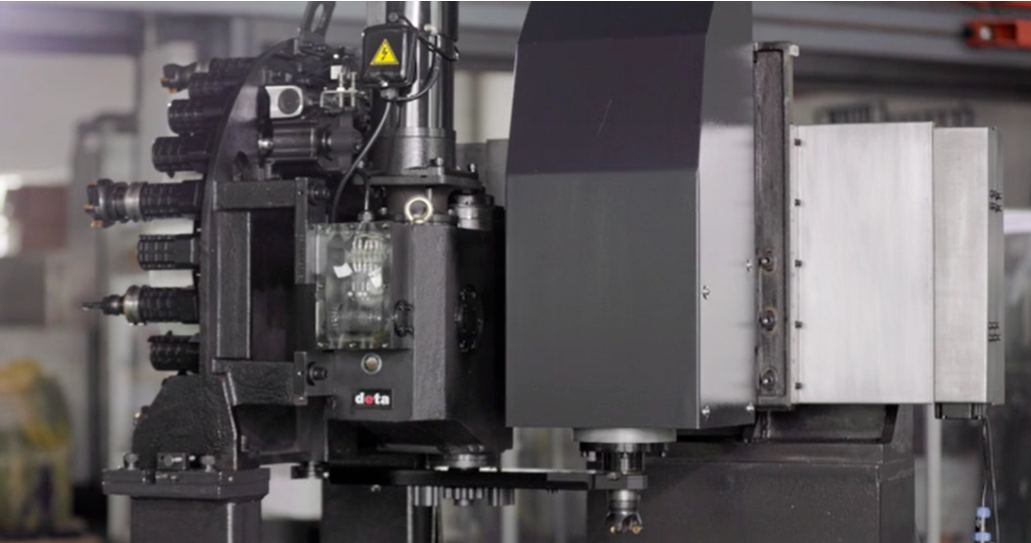

The effect of the lock-down installation of the tool magazine and the column can be separated, which can completely avoid the shortcoming of the side-mounted interface seat of the tool magazine being too long.

Avoid affecting the dimensional accuracy being processed due to the physical vibration caused by the division of the cutter head when the tool is pre-selected in the tool magazine

03 The installation position of the tool magazine

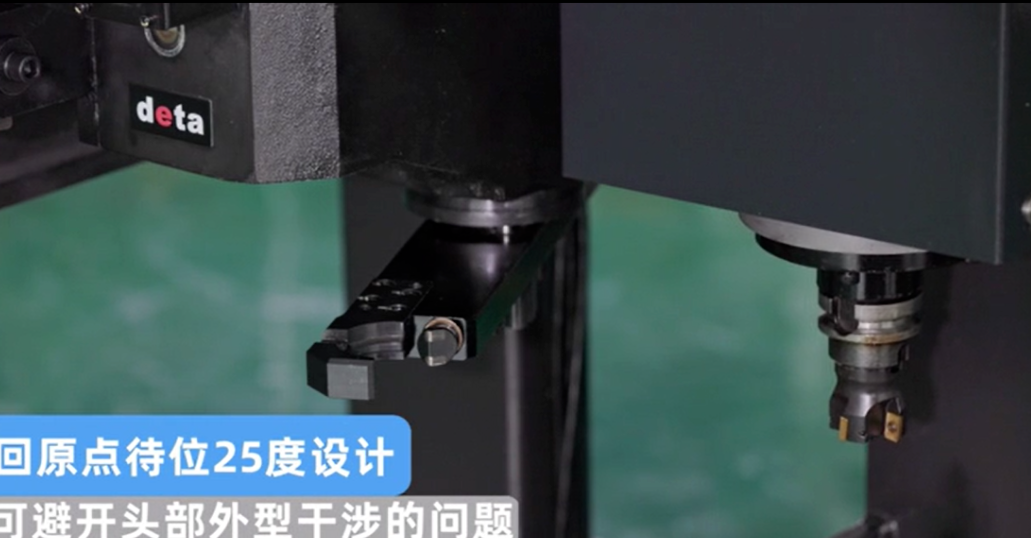

Because the knife arm can be designed to return to the origin and stand by 25 degrees, it can avoid the problem of interference with the shape of the head

It can be closer to the spindle to shorten the length of the tool arm, so that the tool change speed can be steadily increased

This tool magazine is suitable for three-axis moving column machines, small gantry-type machining centers, and portal-type vertical machining centers. It has the characteristics of flexible installation position, short tool arm, fast tool change speed, and avoids workpiece interference.

Home

Home Products

Products Telephone

Telephone Message

Message