The tool magazines of more than half of the factory machines in Taiwan are produced by Deda, but how to meet the different needs of customers? Deda exclusively builds a flexible automated production line, and also gets the ticket to Industry 4.0.

Gold thin-frame glasses, wearing a trendy floral shirt with white trousers, this tasteful uncle who has always refused to be photographed by the media is Huang Yaode, chairman of Deda Machinery, the head of the world's largest tool magazine manufacturer.

The so-called "knife magazine" is one of the important components in the CNC machine, and its function is to store the processing tools and auxiliary tools.

The quality of Deda’s tool magazines is not inferior to that of Germany and Japan, but the price is very competitive. More than half of the working machines in the factory in Taiwan come from this hidden champion.

Although he was born in the Industrial Technology Research Institute, Huang Yaode has more effective thinking than ordinary technical obsessives. This also allows him to have a unique method on the road to Industry 4.0, that is, to do it himself with his own flexible automation.

Huang Yaode revealed that because outside manufacturers are too expensive, he recruited teams and start-up companies at the beginning. After investing 10 million yuan a year in the past four years, Deco, which was invested by Deda, finally successfully built a flexible automated production line last year to solve the problem. plan.

"This production line can produce 57 kinds of parts," he said proudly. Converting the labor cost, the benefit is that it can save about 100 manpower in the past.

Something stronger than amortizing costs.

At present, four flexible automated production lines have been built in the Deda factory. The average equipment cost of one is about 25 million yuan. In addition to the development cost and software and hardware engineer fees, he originally planned to do business with the outside world after successful development. "But people were scared away when they heard that I had opened a production line of 60 million yuan," he said without changing his blunt character.

That being the case, Huang Yaode changed his mind, "Just make it your own." He pinched his fingers and counted. The annual cost of the production line is 25 million, and it can bring 10 million profits a year, which means that it can be recycled in two and a half years. ; If four lines are built every year, "After four years, I will earn 40 million yuan a year, which means that the hardware part will be amortized. In the sixth year, my input cost and management and marketing expenses will also be equal, and I will earn money after that." .”

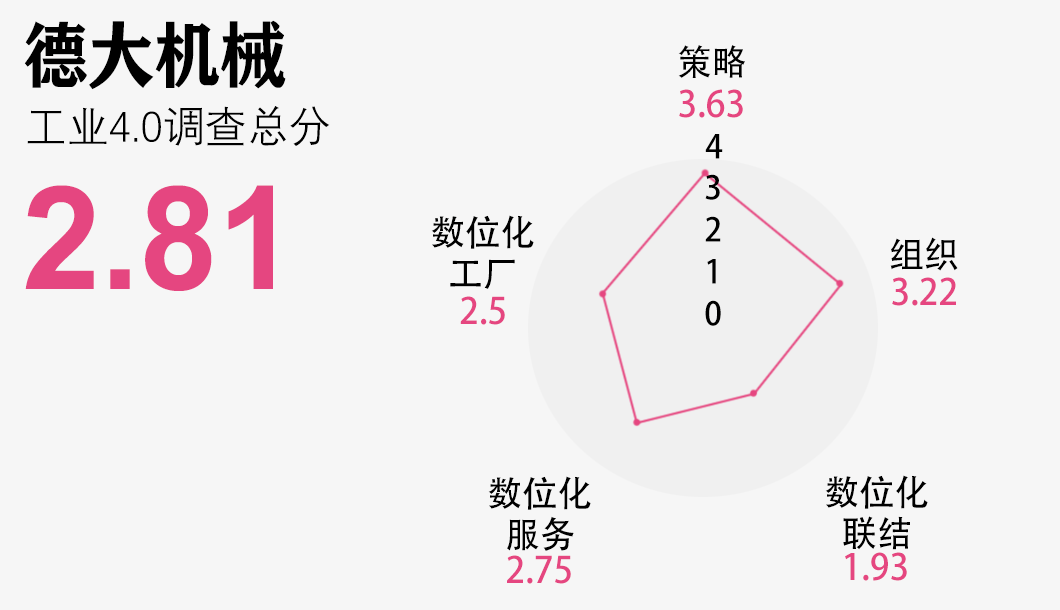

He smiled and said that it may sound like a bad investment, "But don't forget that I got one thing, which is the ticket to enter flexible automation," he admitted frankly, although this is not yet the level of Industry 4.0, but For the mechanical parts industry, which generally does not even have real-time monitoring capabilities on the production site, he is very clear that this is the state that best suits his needs. (Editor in charge: Wu Tingyun)

Home

Home Products

Products Telephone

Telephone Message

Message